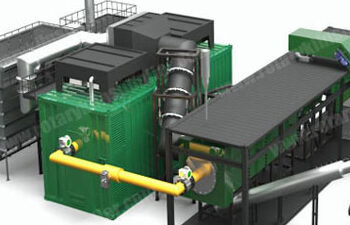

Biomass Carbon- Vapor Co-Production Plant

Integration of material carbonization and vapor production based on gas therefrom.

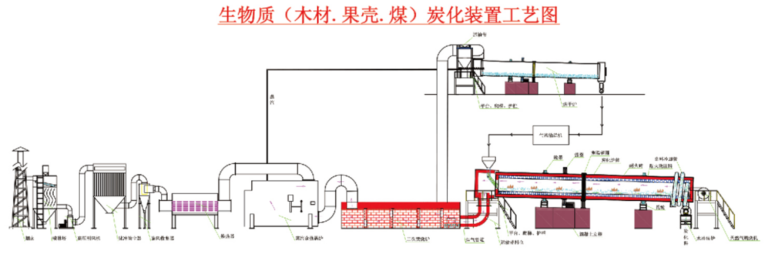

Biomass Carbon-Vapor Co-Production Plant is designed for Biomass carbonization or biochar production to produce activated carbon and steam from biomass. This process involves heating biomass materials in an oxygen-deficient environment to reduce non-carbon elements, essential for the activated carbon manufacturing process. The equipment typically includes a silo, elevator, feeder, furnace body, refractory material, rotating device, temperature measuring device, PLC control cabinet, cooling device, settling chamber, steam waste heat boiler, fan, and dust removal device. This equipment is crucial for producing high-quality activated carbon and steam, which can be used in various industrial applications. The process is efficient and environmentally friendly, making it a valuable addition to industries focused on sustainability and resource optimization.

Biomass Carbonization System Model Parameters

| Model | AGBC-300 | AGBC-500 | AGBC-1000 | AGBC-1500 |

|---|---|---|---|---|

| Feeding Capacity | 4-6m³/h | 6-8m³/h | 10-15m³/h | 18-22m³/h |

| Working Method | Continuous Cracking | |||

| Applicable Raw Materials | All kinds of waste biomass, such as sawdust, coconut shell, palm shell, rice husk, straw, bamboo, etc. civil sludge, municipal sludge, industrial sludge, etc. | |||

| Furnace Size(M) | Φ1.6,Length8 | Φ2,Length10 | Φ2.6, Length12 | Φ3.3 ,Length12 |

| Applicable Fuel | Diesel, Natural gas, Liquefied petroleum gas (LPG), Biomass waste, Biomass syngas, etc. | |||

| By-product (optional) | Biochar, Wood tar, Wood vinegar, Heat, Electricity, Carbon sink | |||

| Emission Standard | EU2019 | |||

| Type of Heating | Indirect Heating | |||

| Power (standard configuration) | 55KW | 75KW | 95.8KW | 145KW |

| Floor Area (L*W*H) (Standard configuration) | 15*8*7m | 29*8*8m | 35*8*9m | 55*8*10m |

| Weight (Standard) | 49ton | 65ton | 77ton | 127ton |

| Furnace Material | Q245R+310s | |||

| Working Pressure | Negative Micro-pressure | |||

| Structure | Three Cylinders And Three Furnaces | |||

| Feedstock Requirement | Size: ≤20mm; Moisture: ≤ 15%; Flow Properties | |||

| Flue Gas Purification Type | Dry Dust Removal | |||

| Working Hours | 7500h/year | |||

| Cooling Method | Water Cooling Heat Exchange | |||

| Noise (decibels) | ≤65 | |||

Active Carbon Equipment Activation Process

Gallery