Activated carbon plants are essential for producing activated carbon, a highly porous material widely used for purification and filtration processes. If you’re considering building one, understanding the costs involved is crucial. Let’s break down the factors, expenses, and investment details to give you a clear picture. Well you can get a quote How Much is Activated Carbon Plant?

What is an Activated Carbon Plant?

An activated carbon plant is a specialized facility designed to produce activated carbon from various raw materials like coconut shells, wood, or coal. These plants use advanced thermal and chemical processes to activate carbon’s porous structure, enhancing its absorption capabilities.

Uses of Activated Carbon

Environmental Applications

- Air purification systems

- Water filtration processes

- Gas purification in industrial settings

Industrial Applications

- Solvent recovery systems

- Food and beverage processing

- Pharmaceutical purification

Medical and Food Industry Applications

- Poison treatment in emergency care

- Decolorization of food products

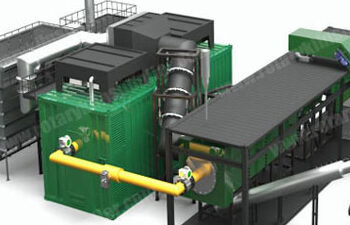

Key Components of an Activated Carbon Plant

Raw Material Processing Unit

This section handles the crushing, drying, and cleaning of raw materials before activation.

Activation Furnace/Kiln

The core of the process, where carbonization and activation take place.

Cooling and Screening System

These units cool down the activated carbon and sort it by particle size.

Packaging and Storage Units

Proper packaging equipment ensures the activated carbon is securely stored for transport or sale.

Types of Activated Carbon Plants

Small-Scale Plants

- Capacity: 1-5 tons per day

- Suitable for startups or specialized industries

Medium-Scale Plants

- Capacity: 5-20 tons per day

- Best for regional markets or medium-sized businesses

Large Industrial Plants

- Capacity: Over 20 tons per day

- Ideal for large-scale production and global supply chains

Factors Influencing the Cost of an Activated Carbon Plant

- Plant Size and Capacity: Larger plants naturally cost more due to greater equipment needs.

- Type of Raw Materials Used: Some materials require extra processing steps.

- Technology and Equipment: Advanced automated systems increase costs but improve efficiency.

- Labor and Operational Costs: Varies significantly based on region and plant complexity.

- Location and Infrastructure: Transport logistics, utilities, and accessibility impact costs.

Average Cost Range, How Much is Activated Carbon Plant?

Small-Scale Plant Costs

- Estimated Cost: $100,000 – $300,000

Medium-Scale Plant Costs

- Estimated Cost: $400,000 – $1 Million

Large-Scale Industrial Plant Costs

- Estimated Cost: $1 Million – $5 Million (or more depending on size and technology)

Breakdown of Key Expenses

- Equipment Costs: Activation kilns, crushers, conveyors, etc.

- Installation Costs: Construction, electrical wiring, and piping

- Maintenance and Operation Costs: Routine cleaning, repairs, and staffing

Cost-Saving Tips for Building an Activated Carbon Plant

- Choosing Cost-Effective Materials: Select raw materials that are abundant and affordable.

- Efficient Process Design: Implement energy-saving strategies.

- Investing in Energy-Efficient Equipment: Reduces long-term operational costs.

Return on Investment (ROI) Considerations

- Revenue from Activated Carbon Sales: Calculate expected income from product sales.

- Operational Efficiency for Profit Maximization: Automation and smart design can improve margins.

Environmental Regulations and Compliance Costs

Ensure your plant follows local environmental standards, which may require additional investment in emission control systems.

How to Choose the Right Supplier for Your Activated Carbon Plant

- Evaluating Supplier Reputation: Check reviews, testimonials, and past projects.

- Comparing Pricing and Equipment Quality: Ensure cost-effectiveness without sacrificing performance.

Potential Challenges in Setting Up an Activated Carbon Plant

- Technical Challenges: Ensuring equipment calibration and process stability.

- Supply Chain Issues: Securing consistent access to raw materials.

Case Study: Successful Activated Carbon Plant Implementation

Example: A mid-sized plant in Southeast Asia achieved a 30% ROI within three years by optimizing its kiln efficiency and securing reliable coconut shell suppliers.

Conclusion

Building an activated carbon plant is a significant investment, but with proper planning and strategy, it can be highly profitable. From understanding costs to implementing efficient processes, each step requires careful consideration. Whether you’re aiming for a small-scale setup or a large industrial facility, strategic investment decisions will lead to success. And How Much is Activated Carbon Plant? if we ask from the source manufacturer

FAQs

- What is the lifespan of an activated carbon plant?

- With proper maintenance, most plants can operate efficiently for 15-20 years.

- How can I reduce the operational cost of my activated carbon plant?

- Investing in energy-efficient equipment and streamlining production processes are key strategies.

- Which raw materials are best for activated carbon production?

- Coconut shells, wood, and coal are the most common choices for quality results.

- Is activated carbon plant installation complex?

- While complex, hiring experienced engineers and suppliers simplifies the process significantly.

- What industries demand activated carbon the most?

- Water treatment, air purification, and pharmaceutical sectors are major buyers.

- From the Main Source, How Much is Activated Carbon Plant?

- You can Aways ask Guanbaolin Carbon Industry Ltd. for a Qoute

[…] Try reading this it will be explained further here. […]