Uses of Hazardous Waste Activated Carbon Regeneration Plant

Activated carbon is a powerful adsorbent widely used in industries to remove contaminants from air, water, and chemical processes. However, once it reaches saturation, its effectiveness diminishes, requiring either disposal or regeneration. A Hazardous Waste Activated Carbon Regeneration Plant plays a crucial role in restoring the adsorptive capacity of spent activated carbon, making it reusable and reducing environmental impact. This blog explores the various applications and benefits of such a plant.

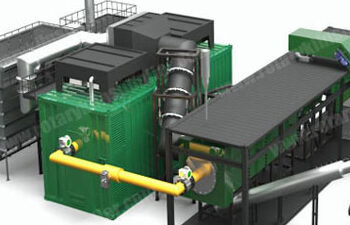

What is a Hazardous Waste Activated Carbon Regeneration Plant?

A Hazardous Waste Activated Carbon Regeneration Plant is a specialized facility designed to treat and restore used activated carbon that has adsorbed hazardous materials. The process typically involves thermal or chemical methods to remove contaminants, allowing the carbon to be reused multiple times.

Key Uses of a Hazardous Waste Activated Carbon Regeneration Plant

1. Industrial Wastewater Treatment

Industries such as chemical manufacturing, pharmaceuticals, and textiles generate wastewater containing toxic chemicals. Regenerated activated carbon is used to purify this wastewater by adsorbing organic pollutants, heavy metals, and hazardous compounds, ensuring compliance with environmental regulations.

2. Air Purification in Industrial Processes

Many industries release volatile organic compounds (VOCs) and other harmful gases into the atmosphere. Regenerated activated carbon helps capture and neutralize these pollutants in air filtration systems, contributing to cleaner and safer air.

3. Groundwater Remediation

Hazardous waste sites often lead to groundwater contamination. Regenerated activated carbon is used in groundwater treatment to remove pollutants such as pesticides, petroleum hydrocarbons, and industrial solvents.

4. Pharmaceutical Industry Applications

The pharmaceutical sector relies on activated carbon to remove impurities from drug formulations and wastewater. A regeneration plant ensures continuous availability of high-quality activated carbon, reducing costs and environmental impact.

5. Gold Recovery in Mining

Activated carbon plays a vital role in gold extraction through the carbon-in-pulp (CIP) and carbon-in-leach (CIL) processes. Regeneration ensures that the carbon remains efficient in absorbing gold from ore leach solutions, optimizing extraction efficiency.

6. Chemical Processing Industry

Many chemical processes require activated carbon for purification and separation tasks. A regeneration plant ensures a sustainable supply of high-performance activated carbon for such applications.

7. Food and Beverage Industry

Activated carbon is widely used in the food and beverage industry for decolorization, deodorization, and purification of products such as sugar, edible oils, and beverages. Regeneration ensures consistent quality and cost-effectiveness.

8. Mercury Removal in Power Plants

Coal-fired power plants use activated carbon injection (ACI) systems to capture mercury emissions. Regeneration facilities help maintain the efficiency of these systems, reducing environmental pollution.

9. Oil and Gas Industry Applications

The oil and gas sector utilizes activated carbon for gas purification, hydrocarbon recovery, and wastewater treatment. A regeneration plant ensures a steady supply of reusable activated carbon, reducing operational costs.

10. Electronics and Semiconductor Industry

High-purity activated carbon is essential for the electronics and semiconductor industry, particularly in air and water purification processes. Regeneration maintains the required carbon quality standards.

11. Medical Waste Treatment

Hospitals and healthcare facilities generate hazardous waste that requires effective treatment. Activated carbon is used in medical waste incineration systems to capture toxic emissions, and regeneration plants ensure continuous supply and cost efficiency.

12. Paint and Coatings Industry

The paint and coatings industry uses activated carbon to adsorb solvent vapors and remove unwanted impurities from raw materials. Regeneration plants support sustainability efforts by reducing waste and resource consumption.

13. Automotive Industry Applications

Activated carbon is widely used in vehicle emission control systems to reduce harmful gases. Regeneration facilities ensure that used carbon can be effectively recycled and reused in catalytic converters and air filters.

14. Printing and Packaging Industry

Printing and packaging companies utilize activated carbon to remove solvent fumes and odors from the air. Regeneration plants contribute to efficient air pollution control measures.

15. Sustainable Waste Management

By regenerating activated carbon instead of disposing of it, industries can reduce waste generation, lower environmental impact, and promote sustainability. This is particularly crucial in hazardous waste management.

Conclusion

A Hazardous Waste Activated Carbon Regeneration Plant plays a crucial role in multiple industries by restoring the functionality of spent activated carbon. It enables cost savings, enhances sustainability, and ensures regulatory compliance across various applications. By investing in regeneration technology, industries can reduce their environmental footprint while maintaining efficiency in purification and filtration processes.

FAQs

1. How does an activated carbon regeneration plant work?

A regeneration plant typically uses thermal or chemical processes to remove adsorbed contaminants from spent activated carbon, restoring its adsorption capacity for reuse.

2. Is regenerated activated carbon as effective as new activated carbon?

Yes, In Guanbaolin carbon industry it isproperly regenerated activated carbon retains its adsorptive properties and can perform similarly to new carbon in most applications.

3. What industries benefit the most from activated carbon regeneration?

Industries such as wastewater treatment, pharmaceuticals, mining, food processing, power generation, and oil and gas greatly benefit from carbon regeneration.

4. How often can activated carbon be regenerated?

Activated carbon can be regenerated multiple times, but its lifespan depends on the type of contaminants it absorbs and the regeneration method used.

5. What are the environmental benefits of activated carbon regeneration?

Regeneration reduces waste disposal, lowers the need for fresh carbon production, conserves resources, and minimizes pollution, making it a sustainable choice for industries.

Please don’t forget to leave a review.

Explore more by joining me on Patreon